Crushing It: Terex Takes the Lead in Telematics

- Blog

- Heavy Industry

- Crushing It: Terex Takes the Lead in Telematics

- Mar 08, 2017

- Lina Paerez

Discover how an extensive custom development project with ORBCOMM has seen Terex Materials Processing become the first OEM to provide remote real-time tracking and diagnostics for crushing and screening machines.

Terex Corporation is a global manufacturer of lifting and material processing products and services delivering lifecycle solutions that maximize customer return on investment. Major Terex brands include Terex, Genie, Powerscreen and Demag. Terex solutions serve a broad range of industries, including construction, infrastructure, manufacturing, shipping, transportation, refining, energy, utilities, quarrying and mining. Terex offers financial products and services to assist in the acquisition of Terex equipment through Terex Financial Services.

Powerscreen® and Terex Finlay, brands of Terex Corporation, are world leaders in the design, production and supply of mobile, heavy-duty crushing and screening equipment for use in mining, quarrying, construction, demolition and recycling and have selected ORBCOMM real-time tracking and diagnostics.

In recent years, telematics technology has become standard on ‘yellow iron’ construction and heavy machines worldwide, helping distributors, owners and operators to maximize the performance, life cycle, safety and value of their equipment. Terex spotted a prime first-mover opportunity to add value to its offering and improve the customer experience by adding telematics capabilities to crushing and screening equipment.

Crushers and screeners are highly specialized, high-value machines. Ranging from 30-120 metric tons in weight, crushers are priced in the hundreds of thousands of dollars. Equipment operates in harsh and often remote environments.

Machines must be set up properly for the specific job in hand and tuning requirements vary from site to site, as no two ores or rocks are ever identical. “It’s not a single commodity being produced here; there are complex variables to consider,” says Barry McMenamin, Group Electrical Technology Manager at Terex Materials Processing. Among other issues, failure to properly tune machines can result in the final, processed material not meeting the desired specification.

“The cost, complexity and remote nature of crushing and screening operations all added up to a compelling case for introducing telematics. We are in a competitive market and are continuously looking for ways to differentiate our product,” explains Mr. McMenamin. “Our philosophy is to lead and set ourselves apart. Others compete, as do we, on price, TCO and running cost. With telematics, we set out to give the market innovative features. With ORBCOMM’s support, we made the decision to differentiate ourselves and give our dealers and customers more value.”

The Project, Partnership, Solution

Terex engaged ORBCOMM and the two companies began an intensive 18-month process working closely together to define the project requirements and the technical scope.

Terex engaged ORBCOMM and the two companies began an intensive 18-month process working closely together to define the project requirements and the technical scope.

“The project has been very much hand-in-hand and a real learning curve for both Terex and ORBCOMM,” says Mr. McMenamin, who has led the endeavour for Terex since its inception. “We’ve had access to some very smart individuals in ORBCOMM who helped us shape our offering and a lot of new features and functions have come off the back of the collaboration.” Terex has also valued the ability to run a single project with a single provider: “It’s a fresh approach for someone who owns data to also offer solutions.”

The result of extensive collaboration was a customized end-to-end telematics solution including:

- A cloud platform for data analytics and reporting, tailored by ORBCOMM to meet the specific requirements from Terex

- Robust tracking and monitoring hardware — devices, sensors and antennas — integrating proprietary ORBCOMM and third-party technology

- 24/7 global connectivity over cellular and satellite via ORBCOMM’s own satellite network and alliances with top-tier terrestrial service providers

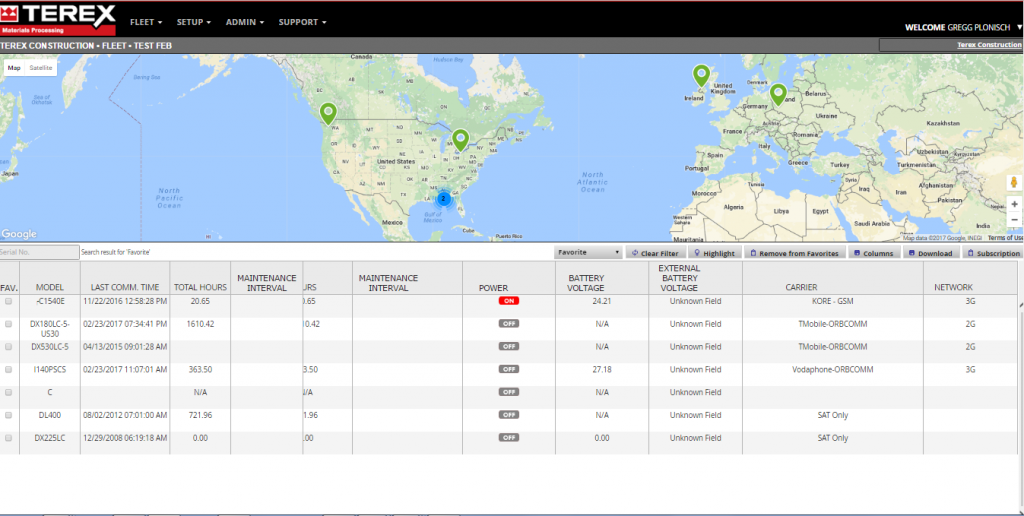

System users now have instant access to comprehensive global data on equipment location, start and stop times, fuel consumption, tonnages, cone settings, wear rates, operating hours, maintenance, service status and more.

Information can be viewed on PC, tablet and smartphone, with the user interface displaying clear dashboard data for ‘at-a-glance’ metrics and diagnostics. The system generates pre-set alarms, alerts and error messages, enabling prompt response to production and machine issues. Additionally, users are notified automatically when their machines are operated outside of set hours and location.

“We are especially pleased with ORBCOMM’s customized web portal, which has enabled us to easily monitor our fleet of machinery and provide operational efficiencies and cost savings to our customers right away,” notes Mr. McMenamin.

Rollout and Benefits

Since starting rollout in 2015, Terex has added telematics capability to over 650 crushers in the existing global fleet and is currently activating some 35-45 new units per month. Terex has white labelled its custom solution from ORBCOMM into two market-facing technology programs—Powerscreen Pulse and Terex Finlay T-Link—and now offers telematics on all new machines.

Beyond what Terex had initially expected to gain from the solution, ORBCOMM has been able to add highly specialized features since the initial deployment. For instance, the system integrates specialized sensors that measure wear-and-tear on critical parts and accurately predict and notify users they are due for replacement. This feature has enabled preventive maintenance—something that could not be achieved with an off-the-shelf solution.

Maintenance matters

More effective maintenance and servicing are among the key benefits of remote real-time monitoring, observes Mr. McMenamin. For instance, knowing the actual running hours enables OEM, distributors and customers to predict precisely when a machine needs to be serviced.

The same applies to wear-and-tear. Crushers and screeners have components that wear out, equipment parts doing the crushing are specifically designed to be replaced, he explains. A conventional maintenance regime cannot accurately account for other reasons that may account for wear and tear, including extra-hard use.

Remote sensor-based monitoring can prevent premature equipment expiry, ensure machines are producing at full performance and protect residual value. Monitoring wear rates also allows dealers and users to anticipate replacement parts and ensure they are available as soon as needed.

Advantage to the dealer

As well as helping Terex distributors optimize their maintenance, parts and service operations, track machine location and utilization and ensure accurate billing, telematics enables them to capture full service records—particularly important for rental equipment that will need to find another customer at the end of the hire period. “Our goal is to give dealers and customers the chance to move to a validated service record, resulting in better residual equipment value,” says Mr. McMenamin.

“This technology will allow our distributors to redefine what constitutes good service,” says Mr. McMenamin. Getting the full value out of telematics will likely require some re-evaluation and change to the business model, he acknowledges: “For some of our dealers we are growing the capability and taking the journey with them.”

Value for customers

The value add for customers is significant, giving them all the familiar functions of telematics on yellow iron, but fully adapted to the needs of crushing and screening operations. As well as the ‘basics’ of remotely tracking machine location, ID and status anywhere in the world, they can:

- Monitor engine hours to plan servicing for increased uptime

- Assess production tonnages and fuel usage and evaluate fuel costs per ton to improve profitability

- Detect theft or unauthorized use with geofences and timefences

- Maximize equipment uptime with timely maintenance carried out following service alerts

Additionally, the system provides statistics and analytics to inform management decisions, generating insights to drive cost savings and optimize fleet planning based on idle versus working time.

OEM benefits

Terex also anticipates real benefits from better insights into the real-world performance and operation of its machines, using operating and diagnostics data to inform design and manufacturing improvements.

Says Mr. McMenamin: “We are already learning a lot about how our equipment is used and will use this to drive improvements. We have a very strong ethos of continuous development and the data from the ORBCOMM telematics solution will help us engineer in more reliability, uptime and fuel efficiency.”

Looking to the Future

Going forward, the company will conduct further data analysis to identify additional areas for savings and improvements. Meanwhile, Terex continues to work closely with ORBCOMM to expand the system’s technological capabilities. A new maintenance module is currently in development and testing, which will allow customers to streamline service schedules with features including:

- Equipment page displaying any alerts associated with a model

- Record page logging maintenance performed on a machine, parts replaced and status for every part

- Dashboard widget listing equipment coming due or due for maintenance at OEM determined intervals

- Automated alerts for upcoming maintenance

- System log giving detailed information on tools and parts required for upcoming service

Plans for the first half of 2017 include integrating ORBCOMM’s latest dual satellite-cellular heavy equipment tracking device, the PT 7000, into the existing solution, as well as adding telematics to screeners. Currently in test by Terex, the PT 7000 will deliver more functionality and will operate on ORBCOMM’s recently-enhanced OG2 satellite data service for improved performance and coverage.

Plans for the first half of 2017 include integrating ORBCOMM’s latest dual satellite-cellular heavy equipment tracking device, the PT 7000, into the existing solution, as well as adding telematics to screeners. Currently in test by Terex, the PT 7000 will deliver more functionality and will operate on ORBCOMM’s recently-enhanced OG2 satellite data service for improved performance and coverage.

As the system starts to generate a truly meaningful quantity of information, Terex is also looking to big data as the future, allowing the company to perform advanced analytics on the mass of historical data collected from field equipment. “We see the opportunity to gain a deep understanding of the product duty cycle and lifecycle so we can improve design and manufacturing,” says Mr. McMenamin.

Download the full Terex Case Study here.

With over 15 years of marketing experience at companies big and small, Lina Paerez leads ORBCOMM’s global marketing team, driving key positioning strategies, product launches, demand generation and brand awareness.